|

|

|

| You are here: Home> Products > Gate |

|

|

|

|

|

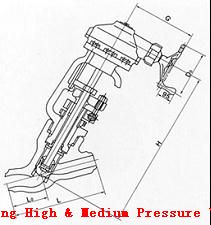

| Product Name:DC-type welding globe valve |

| Product Classification:Globe valve |

| Product Introduction: |

J65H high temperature and pressure valve, the valve is turned on or off the relatively short trip, but very reliable cut-off function. Such cut-off valve so that the liquid is almost no change in flow direction, and channel angled stem cut-off valve, the valve seat sealing surface and the import and export channels have a certain perspective, the valve body can be made integral. Valve and stem design as a whole structure, to prevent pressure fluctuations caused by the pipeline within the body parts out the possibility of sex, compact, safe to use. According to the high temperature high pressure, the valve body can fully withstand the temperature changes caused by expansion, contraction, and the seat part of the structure of the surface temperature changes will not produce permanent deformation. Lan connection can not be, used welding methods.

|

|

| Description |

Parameters |

Size Chart |

Application |

|

Valve reasonable structure, excellent performance, attractive appearance, suitable for a wide range of pressure, mainly used to connect or disconnect piping in the media, with wear-resistant, high temperature, anti-abrasion performance, long life. Cut-off valve, welded valve, globe valve DC, DC-type welding valve high pressure valve DC-type welding, DC-type welding valve, high temperature and pressure valve

J65H high temperature and pressure globe valve from the valve body, valve cover, valve stem, valve and other components. For the work under the conditions of high temperature and pressure valve, the sealing surface of the working conditions in poor conditions, so the sealing surface of the high performance requirements. Over the years, the widespread use of domestic and foreign prices of precious cobalt chrome tungsten welding the valve sealing surface as the material. To reduce costs, solve problems and improve weld cracks when the valve sealing surface machining performance, you can try in recent years, China developed a series of submerged arc welding of high alloy bonded flux, flux, such as bond No. 137, because of its good performance, prices moderate. J65H Once the high temperature and pressure valve is turned on its valve seat and valve between the sealing surface is no longer in touch with the sealing surface so it's less mechanical wear, valve seat and valve seal is easier to repair or replace components no need to remove the valve from the pipeline to which the valves and pipes welded into one of the occasions is very applicable. Medium through the valve when the flow direction of such change.

|

|

一,Main parts:

|

Part name |

Material grades |

|

Valve body |

WCB |

WC6 |

WC9 |

|

Piston |

A105 |

WC6 |

WC9 |

|

Valve cover |

25 |

12Cr1MoVA |

|

Valve stem |

1Cr17Ni2 |

20Cr1Mo1V1A |

|

Seal ring |

05F |

05F |

Flexible graphite |

|

Four open-loop |

1Cr13 |

20CrMOIVIA |

|

packing |

BSP-600 |

BSP-600 |

|

support |

WCB |

WCB |

|

Stem nut |

ZQAL9-4 |

ZQAL9-4 |

二, the DC-type welding valve order number, size and weight:

|

DN(mm) |

Size (mm) |

weight(Kg) |

|

L |

D1 |

Do |

H |

Lo |

L1 |

|

PN32(320) J565Y-320V type |

|

80 |

390 |

64 |

120 |

750 |

- |

- |

121 |

|

100 |

480 |

108 |

185 |

870 |

- |

- |

212 |

|

125 |

533 |

132 |

218 |

995 |

- |

- |

312 |

|

150 |

610 |

166 |

245 |

1205 |

- |

- |

510 |

|

175 |

750 |

175 |

278 |

1565 |

- |

- |

708 |

|

200 |

762 |

200 |

290 |

1670 |

- |

- |

980 |

|

225 |

850 |

108 |

310 |

1705 |

- |

- |

1060 |

|

250 |

914 |

248 |

348 |

1870 |

- |

- |

1380 |

|

300 |

1041 |

300 |

430 |

2335 |

- |

- |

2824 |

|

P54(140) J565Y-P54140V type |

|

80 |

390 |

64 |

120 |

750 |

- |

- |

130 |

|

100 |

480 |

108 |

185 |

870 |

- |

- |

212 |

|

125 |

580 |

132 |

218 |

995 |

- |

- |

312 |

|

150 |

630 |

166 |

245 |

1205 |

- |

- |

510 |

|

175 |

750 |

175 |

278 |

1565 |

- |

- |

708 |

|

200 |

771 |

200 |

290 |

1670 |

- |

- |

980 |

|

225 |

850 |

108 |

310 |

1705 |

- |

- |

1060 |

|

250 |

930 |

248 |

348 |

1870 |

- |

- |

1380 |

|

300 |

1060 |

300 |

430 |

2335 |

- |

- |

2824 |

|

產(chǎn)品外形及結(jié)構(gòu)尺寸示意圖

|

working principal:J65H high temperature and pressure valve opens the valve seat height channel diameter is typically only 1 / 4, so much smaller than the gate. In the valve body and valve are usually only one sealing surface, and thus the manufacturing process is better, ease of maintenance. Hand wheel clockwise, the working medium from the bottom of the channel into the valve, this time, the sealing force applied must be equal to or greater than the sealing surface must be generated by pressure and the media than the upward force of the and. On the contrary counter-clockwise rotation, the valve into the mouth closed, stop into the media.

Note:1, the hand wheel, lever operated valves can be installed in any position in the pipeline.

2, hand wheels, handles and Wei moving body does not allow for lifting purposes.

3, the flow of media should be consistent with the direction of the arrow shown in the valve body. |

|