|

|

|

| You are here: Home> Products > Gate |

|

|

|

|

|

| Product Name:Welding Hard Seal Butterfly Valve |

| Product Classification:Butterfly valves |

| Product Introduction: |

The butterfly valve, based on introducing the foreign advanced technology, using sophisticated J-shaped flexible seal ring and three eccentric multi-level metal seal structure, and is widely used in the petroleum, chemical industry, metallurgy, water, electricity and many other areas which media temperature ≤425℃.It is used to achieve piping system as an on-off and flow control components. The valve, using three-eccentric structure, valve seat and disc sealing surface are made of stainless steel with different hardness. And have good corrosion resistance and long life. It’s has the bi-directional sealing function and be in line with national GB/T 13927-92 valve press test standard. |

|

| Description |

Parameters |

Size Chart |

Application |

|

Feature

1)Using three-dimensional eccentric structure ,body ring structure or the use of multi-level flexible metal ring, so that the same butterfly valve plate sealing surface contacts are reliable ,can be achieved without leakage of bubble seal.

2) Unique structure, operation flexible, labor-saving, convenience, long service life. 3) High temperature resistance, corrosion resistance, wear-resistant three-dimensional eccentric |

|

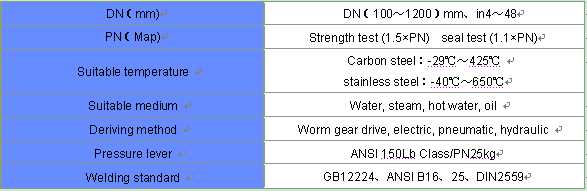

Main parameter

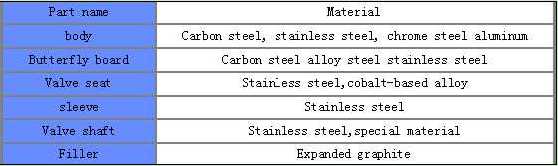

Main parts material

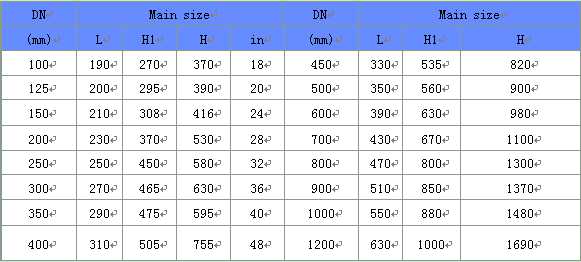

BYD363H/663H/963H/-10/16/25/40/C���、P、R The main external connection dimensions of Welding Hard Seal Butterfly Valve.(unit:mm)

|

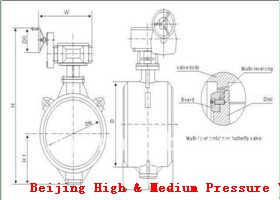

產(chǎn)品外形及結(jié)構(gòu)尺寸示意圖

|

There are the following jobs to do while installing the valve

(1)Clean cavity and the sealing surface; dirt adhesion is not allowed.

(2)Check whether the conjunction of the thread is evenly tightened.

(3)Check whether the packing is compressed in order to keep the seal of the packing.

Check whether the switch button and the porous socket of the electric device are in normal condition when installing the electric valve

(5)Check whether the electrical devices function well. |

|